By info

•

December 20, 2023

Author: Christoph Buchmann, December 18 th 2023 Introduction: The rise of warehouse automation has been nothing short of meteoric. Over the past decade, the sector has witnessed a growth of approximately 15% annually, driven largely by a global surge in e-commerce and the relentless quest for efficiency in supply chain operations. Yet, as we steer towards an era of seemingly boundless technological innovation, there remains a robust case for the integration of often overlooked semi-automated solutions in our warehousing strategies. The Limitations of Full Automation As tantalizing as the prospects of full automation may seem, it isn't always the golden ticket to operational excellence. Full automation demands immense capital, prolonged implementation periods, and oftentimes, a complete overhaul of existing infrastructure. Furthermore, certain tasks remain notoriously challenging for robots. Consider the intricacies of handling fragile ceramics or the unpredictability of packaging oddly shaped, bulky items. These are scenarios where the tactile sensitivity and adaptability of human hands, guided by purely human hand-eye coordination, can often outperform the most advanced robotic counterparts. It's an interplay between mechanized precision and human finesse. Entry-Level Technology: Taking the First Step For businesses that are cautious about diving headfirst into the world of automation, semi-automated systems present a prudent middle ground. These entry-level technologies, besides being more cost-effective, allow companies to dip their toes into automation without the commitment and complexities of a full-scale overhaul. Moreover, they significantly mitigate the risks associated with delays or teething problems that might arise during the integration of fully automated systems. Essentially, semi-automated solutions can act as a bridge, providing tangible benefits while also serving as a preparatory phase for potential future expansions. A Dive into Select Technologies Mobile Racks: These semi-automated storage solutions maximize space efficiency. While the racks move autonomously, the inventory selection and retrieval processes still necessitate human intervention, ensuring flexibility in handling a myriad of items. AMRs (Autonomous Mobile Robots): AMRs, unlike their fully automated counterparts, work alongside human employees, facilitating tasks like the transportation of goods within a warehouse. They enhance productivity without eradicating the human touch from the equation. Deep-Lane pallet radio shuttles: These are specialized storage solutions that autonomously navigate storage lanes. However, the loading and unloading processes are typically semi-automated, ensuring a seamless blend of speed and caution. VLMs (Vertical Lift Modules): VLMs are storage solutions that automatically deliver items to an access point. While the retrieval is automated, the picking process remains human-led, ensuring accuracy and care. A New Dawn for Small and Medium Enterprises As the curtain falls on this discussion, it's pivotal to underscore the transformative potential of semi-automated solutions, especially for smaller businesses. These enterprises often operate under tighter budget constraints, making the prospect of full automation daunting. However, with the suite of semi-automated technologies available, these businesses can now embark on their automation journey, reaping a plethora of benefits ranging from improved efficiency to enhanced accuracy. The fusion of man and machine, in many ways, holds the promise of an optimized, resilient, and dynamic warehousing future. Author: Christoph Buchmann December 18 th 2023 Disclaimer: The views expressed in this paper are solely the opinion of the writer and are not associated with any corporate entity. This is a personal blog. Any views or opinions presented are personal and belong solely to the author and do not represent those of people, institutions, or organizations that the owner may or may not be associated with in a professional or personal capacity unless explicitly stated. Any views or opinions are not intended to malign any organization, company, or individual.

By info

•

August 22, 2023

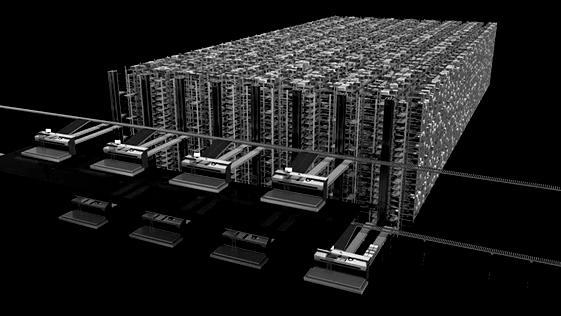

Cube storage systems, with their promise of dense storage and efficient space utilization, have rapidly evolved since their inception. This unique storage paradigm has witnessed various changes and improvements, driven by the constant endeavour to achieve better scalability, versatility, and speed. Let's dive deep into the evolution of these systems, tracing their journey from the early pioneers to today's cutting-edge solutions. The Dawn of a New Era: AutoStore The late 1990s marked the beginning of a revolution in cube storage with the introduction of AutoStore. Founded in 1996 in Norway, AutoStore pioneered the idea of using a grid system combined with robots on top. These robots, equipped with a mechanism to dive into the grid and retrieve bins, changed the landscape of warehousing. It optimized space like never before, with a promise of up to 60% increase in storage capacity compared to manual shelving. AutoStore's success lay in its revolutionary design that allowed it to make efficient use of both horizontal and vertical space, eliminating the need for aisles and making the most out of every square inch of a facility. Ocado's Leap Forward While AutoStore was making waves in Europe, on the other side of the North Sea, Ocado was beginning to make its mark. Established in 2000, the British online supermarket quickly recognized the potential of automated warehousing. Although initially it relied on traditional automation methods, by the mid-2010s, in collaboration with Tharsus, it had developed its own cube storage solution. The result was the Ocado Smart Platform, which showcased a three-dimensional grid system, with robots operating on top. These robots, capable of collaborative operation and making real-time decisions based on the system's needs, offered a fresh perspective on what cube storage could achieve. Their subsequent evolution to Intellistore further enhanced the cube storage philosophy, providing a more intelligent, dynamic, and flexible system. Intellistore This solution provided the much-needed improvement that AutoStore and Ocado didn’t have – instant access to totes. By removing the need to dig for totes, Intellistore offered a cube-based system with much higher performance. As SKU sets and profiles constantly change, it is important to have SKU selectivity, or in other words instant access to the product. Gone were the days of digging. Gebhardt's Entry and the StoreBiter 500 Gebhardt entered the arena with its StoreBiter 500 in the late 2010s. While the basic premise of a grid with robots on top remained consistent, Gebhardt introduced multi-level shuttles. These shuttles were capable of vertical movement within the grid, enhancing the system's speed and efficiency. With their patented technology, Gebhardt promised reduced processing times and better energy efficiency. The Attabotics Take Attabotics, a relatively newer entrant founded in 2015, took the cube storage system concept and gave it a unique spin. Instead of the conventional grid, Attabotics envisioned a system that mimicked the structure of an ant colony. Robots in this system could move both horizontally and vertically, ensuring faster retrieval times. Their compact system was not only space-efficient but also optimized for e-commerce operations, where speed and accuracy were paramount. Gridstore’s Vision Gridstore further expanded on the cube storage idea by emphasizing modularity. Their systems were designed to be scalable, catering to both small enterprises and large corporations. Gridstore's unique selling proposition was its ability to adapt and grow with a company's needs without significant overhauls. Benefits and the Evolutionary Drive So, what fueled this evolution in cube storage systems? The reasons are manifold: Space Optimization: Traditional warehousing methods, with their vast aisles and sprawling footprints, were inefficient. Cube storage systems, with their dense storage philosophy, revolutionized space utilization, a critical factor given the rising real estate costs. Scalability: Companies grew and so did their warehousing needs. Cube storage systems, with their modularity, allowed businesses to scale their operations without the need for massive infrastructural changes. Speed and Efficiency: The e-commerce boom demanded faster processing times. Cube storage systems, with their robotic retrievals, promised (and delivered) faster turnaround times, ensuring that orders could be processed in record times. Accuracy: Human errors in order picking or storage could have costly ramifications. Automated systems significantly reduced these errors, ensuring accurate order fulfillment. In conclusion, the evolution of cube storage systems showcases the warehousing industry's constant quest for better, faster, and more efficient solutions. From the pioneering efforts of AutoStore to the modern innovations of companies like Intellistore and Gridstore, the journey has been marked by innovation and a relentless drive to improve. For market insiders and observers, the cube storage system's story is a testament to the power of innovation and the promise of a more efficient future.

By info

•

August 1, 2023

Why Selectivity Matters for Robotic Goods-to-Person Systems Debunking the myth that Cubic Storage systems don’t have to “dig” for bins as they rely on a natural ABC slotting algorithm Author: Christoph Buchmann, June 2 nd 2023 Introduction: Selectivity matters! Instant access to product (bins) is critical for the operational performance of any Goods-to-Person storage & order fulfillment system. Any multi deep storage configuration naturally leads to reshuffling the bins in front (or above, in case of vertical storage), taking up precious time and valuable performance capacity. In the past there have been claims that cubic storage systems, such as Ocado® or Autostore® do not have to “dig” frequently for bins, as the system relies on a self-generating natural ABC slotting algorithm. However, the math doesn’t support this statement! This white paper is intended to objectively illustrate why cubic storage systems inevitably have to dig for bins in any multi deep storage configuration, how that negatively impacts performance and explain why product (bin) selectivity in a Goods-to-Person system matters and directly influences operational throughput and system performance. It is important to understand that there is no such thing as a “one-size-fits-all” Goods-to-Person system. Just like with cars, there is a wide variety of options built for many different applications. Many of the available Goods-to-Person technologies have their sweet-spot, depending on whether the operation is performance driven or storage driven, depending on ABC profiles, depending on the amount of replenishment storage and other operational factors that must be considered. So, the questions you have to ask yourself are, what are my operational needs and which system is the right one for me? The devil is in the details, but in this post, by using simple mathematical examples, we will help shine some light on the topic of “bin digging” and debunk the myth of “natural ABC slotting”. To dig or not to dig…?